Your cart is currently empty!

Fuel Systems

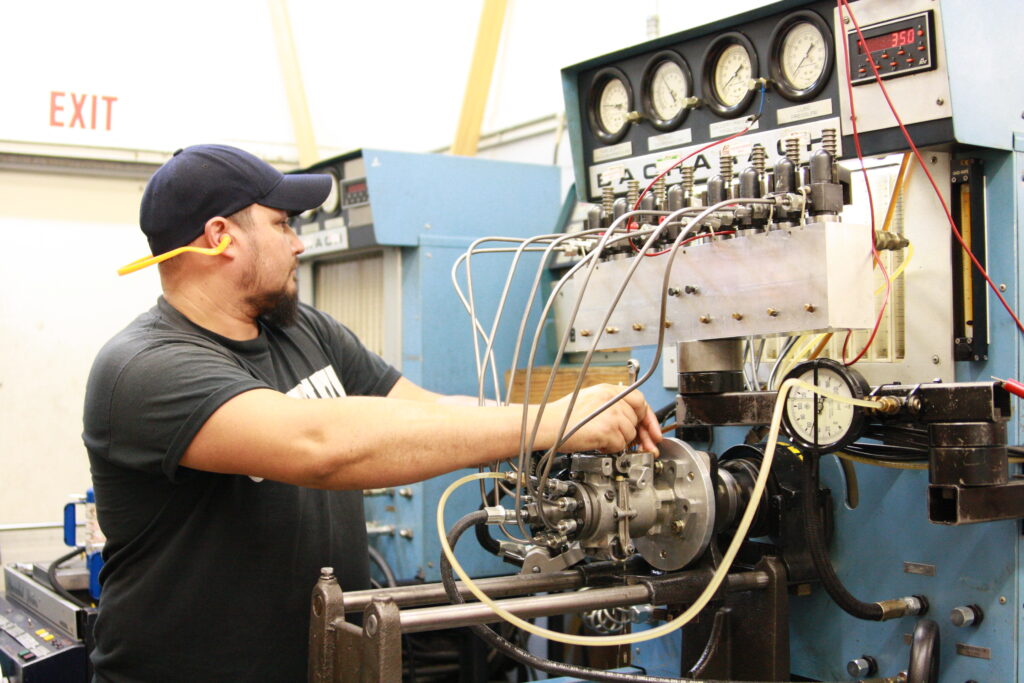

In order for an engine to achieve optimum performance and comply with emissions standards, the fuel delivery system needs to be in perfect working condition. Restoring these precision electromechanical devices to their original specifications requires the right parts, specialized knowledge, and state-of-the-art measuring equipment. Properly servicing or remanufacturing fuel pumps and injectors requires three things:

- Highly-skilled technicians who, as a result of many years of experience and training, are experts at what they do

- Access to original factory replacement parts thru established relationships with OEMs

- Highly-precise calibration equipment and the knowledge of how to use it to achieve original factory specifications

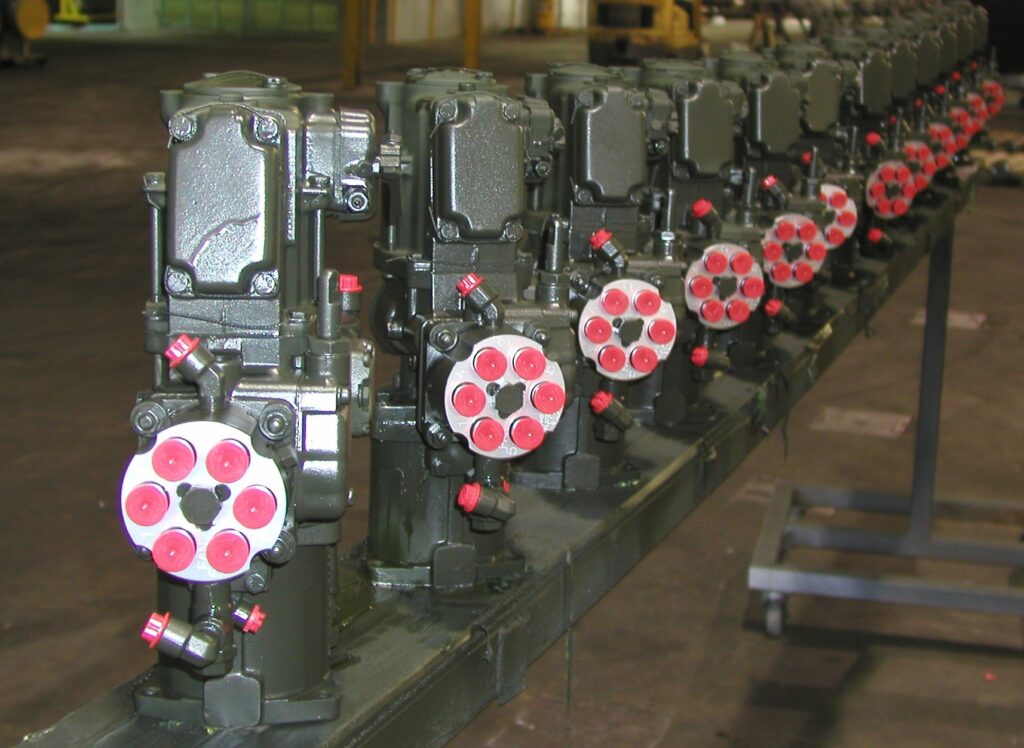

Products remanufactured in the MTP fuel shop are engine turbos, blowers, governors, and fuel pumps. Below is a short description of each part included in the fuel system.

Fuel Injectors

Fuel injection is where fuel is admitted directly to the ICE, or, the internal combustion engine. One of the biggest benefits of fuel injection is undeniably better engine response during intense throttle transitions. MTP has great relationships with the various engine OEMs to obtain replacement parts and testing requirements to diagnose and repair injector malfunctions. The current generation of injectors has become very complex with electronic controls which have made these professional relationships even more important.

Fuel Injection Pumps

A fuel pump is a critical component for military diesel engines where fuel needs to be delivered under low or high pressure. Each fuel pump is calibrated to applicable Technical Manuals. Pumps are calibrated using Bacharach Specialist 10 test benches and a Bacharach PDFM 801 Digital Flow Meter. The MTP fuel shop possesses experienced personnel that have access to OEM specifications and high quality test equipment.

Engine Turbo (Turbocharger)

What exactly is an engine turbo, or, more commonly known as, a turbocharger? In short, the turbocharger increases the performance for both the power and efficiency of an engine. In more detail, a turbocharger is a centrifugal compressor that is governed by a turbo and is operated by exhaust gases. Because more air is able to enter the engine, also known as forced induction, it benefits the engine by increasing its overall performance.

Most of the military diesel engines contain a turbocharger. That is one of the main reasons why we provide the turbocharger service in the first place. There is, however, a limit to the boost pressure allow per engine. This is because if the engine is extremely overworked it could cause permanent damage to its internal hardware, or, could cause overheating which will shut down the entire engine. Therefore, we only use turbochargers that are within the mechanical design and operating range per engine. Like the engines we re-manufacture, turbochargers can be used in a wide variety of applications.

Blowers

Blowers are more commonly referred to as superchargers. A blower is a mechanical device, through forced induction, creates a greater flow of air into the engine. This provides the engine with more oxygen and in turn supports combustion to burn more fuel and increases the power of the engine. The power comes from the extra work that can be done per cycle. Some of the higher horsepower engines in larger military trucks, such as the HEMTT, contain blowers.

Governors

A governor must be installed in the vehicle to help regulate the speed of the engine. How the governor works is that when air comes through towards the engine, it passes the governor and it only allows the amount of air limited by the governor. If too much air is allowed to pass through the engine, then the engine may overwork, or, overheat, and shut down entirely.

It is MTP Drivetrain Services responsibility to ensure that each part in the fuel system is calibrated perfectly to obtain results that fit our customer’s needs.